The Hidden Margin Killers in Your Print Shop — and How Automation Quietly Fixes Them

Let me guess — you’re fighting rising material costs, labor shortages, and clients who want everything yesterday.

But here’s what I’ve learned working with print operations across every segment: the real threat isn’t paper prices.

It’s the hidden waste buried in your workflow—the bottlenecks you’ve normalized, the manual processes you tolerate, and the inefficiencies that compound every single day.

Today, I’m going to show you the five margin killers that sabotage print shops and the automation moves that fix them fast. No theory. No fluff. Just the patterns I’ve seen destroy profitability and the systematic solutions that actually work.

Margin Killer #1: Manual Prepress That Eats Hours

Here’s the scene I see constantly: Your prepress team is drowning in file checks, manual imposition, and endless corrections. Every job requires human intervention. Every mistake requires rework. And every hour your skilled operators spend fixing customer files is an hour they’re not adding strategic value.

The numbers don’t lie. Across wide-format, flexo, offset, and transactional segments, automation adoption is accelerating because manual workflows create cascading delays throughout production. When prepress is your bottleneck, everything downstream suffers.

Let me give you a real example. I worked with VariVerge, a company facing exactly this challenge—no systematic workflow, no visibility into where jobs were stalling, and processes that moved at a crawl. We implemented automation-driven workflows paired with a strategic marketing engine.

The result? 9× traffic increase and a multi-million-dollar growth opportunity unlocked.

The insight here is simple but powerful: When your team stops firefighting prepress tasks, they start finding real growth.

Automated prepress systems handle file validation, imposition, and color management without human babysitting. This doesn’t eliminate jobs—it elevates them. Your people move from reactive firefighting to proactive optimization.

Margin Killer #2: Slow Intake & Approval Loops

“Every job feels like we’re reinventing the wheel.”

I hear this from executives more than any other complaint. And it makes perfect sense—intake friction is the silent killer of print operations.

Think about your current process. A customer submits a job. Someone manually enters specifications. Files go back and forth via email. Approvals get lost in inboxes. Revisions create version control nightmares. By the time the job hits production, you’ve burned hours of labor and frustrated your client.

Here’s what changes with intelligent automation: templated intake forms, automated proofing systems, and smart customer portals eliminate 80% of this friction.

Consider Goelzer’s transformation. They were stuck with outdated systems, no marketing engine, and stalled growth. We brought operational clarity and streamlined their front-end processes.

The outcome? They doubled their client base and unlocked $4.2 million in value.

The critical insight: They didn’t buy a new press—they fixed the front-end friction.

When customers can submit jobs through structured portals with pre-defined specifications, when proofing happens through automated systems with clear approval workflows, when intake doesn’t require your team to be interpreters and project managers simultaneously—everything changes.

Margin Killer #3: Labor Shortages Creating Structural Bottlenecks

Let’s address the elephant in the pressroom: you can’t hire your way out of this problem.

Industry data consistently shows labor shortages as one of the top growth barriers in commercial print. Skilled operators are retiring. Younger workers aren’t entering the trade in sufficient numbers. And the operators you do have are stretched dangerously thin.

But here’s the strategic shift successful shops are making: they’re using automation to fill gaps better than hiring ever could.

Why? Three reasons:

- Predictability: Automated systems don’t call in sick, don’t quit, and don’t need months of training

- Scalability: You can handle volume spikes without adding headcount

- Reduced skill dependence: Less reliance on institutional knowledge trapped in individual employees’ heads

Let me be crystal clear about something: Automation isn’t replacing your people—it’s keeping them from burning out.

When automation handles repetitive tasks, your skilled operators can focus on complex problem-solving, quality control, and continuous improvement. This is how you retain good people—by making their work more meaningful and less exhausting.

Margin Killer #4: Rework Waste Hidden Across Every Run

Color inconsistencies. Missed specifications. Late changes that require reprints.

Every one of these problems feels like a one-off exception. But add them up across a quarter, and you’re looking at significant margin erosion.

The compounding cost of rework is brutal:

- Wasted materials

- Lost press time

- Rushed delivery

- Damaged client relationships

- Demoralized production teams

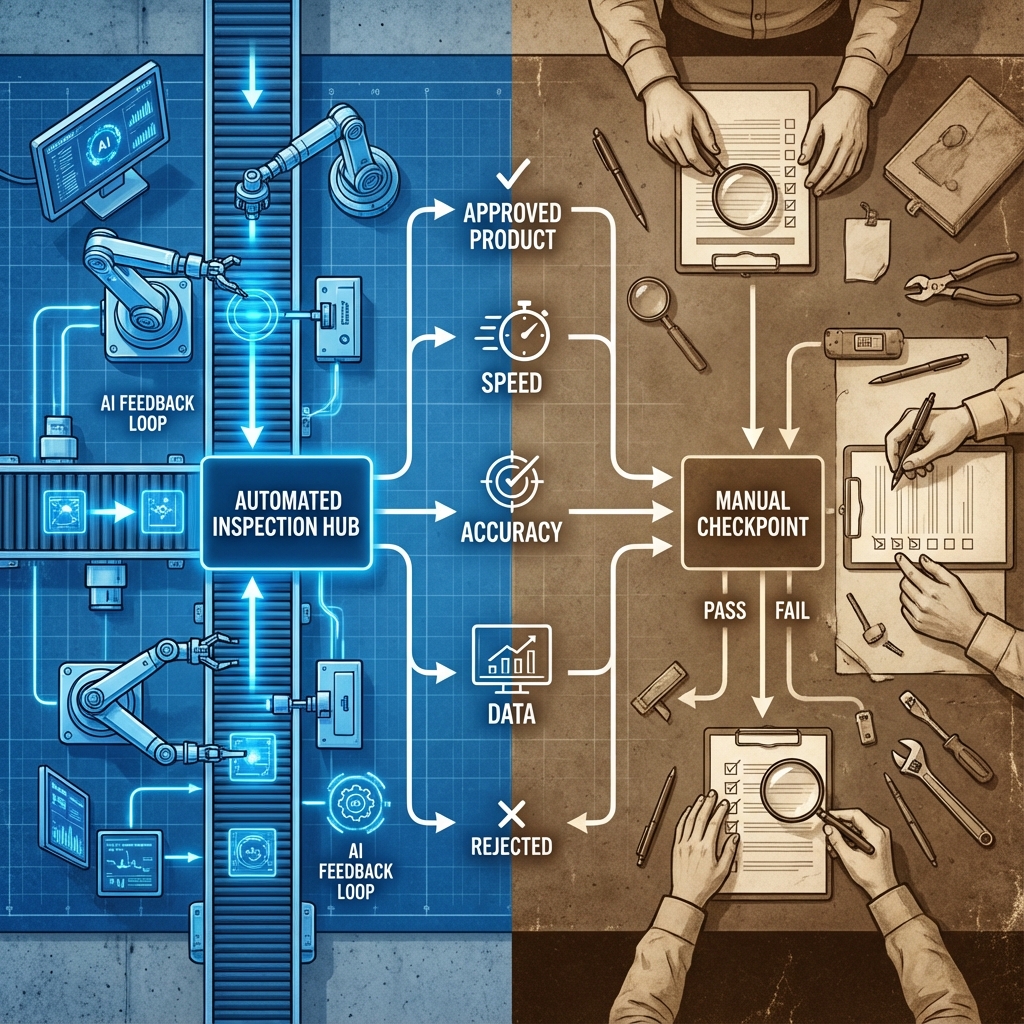

Modern AI-powered quality control systems are changing this equation dramatically. Automated color management ensures consistency across jobs and across time. Intelligent preflighting catches specification mismatches before they reach the press. Real-time monitoring during production identifies problems within seconds, not after thousands of impressions.

This isn’t futuristic technology—it’s available now and being deployed across offset, digital, and flexo operations to reduce makeready time, improve color accuracy, and cut rework to near-zero levels.

Margin Killer #5: Reactive Scheduling & No Real-Time Visibility

Here’s what reactive scheduling looks like in too many shops:

- Surprise overruns that cascade into delayed jobs

- Unplanned downtime that throws off the entire day

- Manual job routing based on whoever shouts loudest

- No visibility into actual capacity until you’re already overbooked

This isn’t a scheduling problem—it’s a data problem.

Intelligent automation combined with modern scheduling tools gives you something revolutionary: real-time visibility into actual production capacity.

You can see where jobs are in real-time. You can identify bottlenecks before they cause delays. You can make data-driven decisions about which jobs to prioritize. You can increase throughput without buying new equipment simply by optimizing how you use what you already have.

Industry research on workflow automation consistently shows 15-30% throughput improvements when shops move from reactive to intelligent scheduling systems.

The Automation Fix: What Actually Changes in a Print Shop

Let’s break this down into the specific transformations that matter:

- Intake & Job Creation

Replace email chaos with templated portals, automated specification capture, and structured customer interfaces. Jobs enter your system complete and correct from day one.

- Prepress & Proofing

Implement automated file checks, intelligent imposition, color management, and digital proofing workflows. Eliminate the back-and-forth that kills timeline and morale.

- Production & Pressroom

Deploy AI-driven predictive maintenance, intelligent scheduling, and inline quality control. Catch problems before they become expensive mistakes.

- Sales & Marketing Automation

This is where many print executives miss the connection, but the principle is identical.

I worked with Elite Health Online to implement automated marketing sequencing and systematic customer acquisition processes. The result: 2.5× customer acquisition improvement using automation to eliminate human bottlenecks.

The insight is universal: Whether it’s customer acquisition or production workflow, eliminate human bottlenecks and growth compounds.

The Real Point: You Don’t Need More Machines — You Need Better Systems

This is the pattern I’ve seen repeatedly across every transformation I’ve guided:

- VariVerge didn’t need bigger capacity—they needed workflow clarity

- Goelzer didn’t need more equipment—they needed front-end efficiency

- Elite Health Online didn’t need more salespeople—they needed systematic processes

Every major leap came from fixing process friction, not buying hardware.

Your next competitive advantage isn’t sitting in an equipment catalog. It’s hiding in the gaps between your current workflow steps, waiting to be optimized.

Quick Diagnostic: 5 Questions Every Print Executive Should Ask This Week

Take five minutes and honestly answer these:

- Where do jobs slow down before they hit the press? Map your actual workflow and identify the delays.

- How many steps are still manual that don’t need to be? List every touch point that requires human intervention.

- What work is your team doing that automation could do better? Be ruthless about this assessment.

- Where do clients get frustrated in your current process? Listen to their complaints—they’re showing you your bottlenecks.

- Which bottlenecks would disappear with a clearer workflow? Imagine your ideal state and work backward.

Your answers will reveal exactly where automation delivers maximum ROI.

Key Takeaways

- Manual prepress workflows create cascading delays and prevent your team from focusing on strategic growth

- Intake friction costs you more than material waste—fix the front-end and watch margins improve

- Labor shortages require systematic solutions, not just hiring strategies—automation fills gaps predictably

- Hidden rework costs compound silently; automated QC catches problems before they reach the press

- Reactive scheduling leaves money on the table; intelligent automation increases throughput without new equipment

- Process optimization delivers faster ROI than equipment upgrades—fix workflow friction first

- Systematic automation principles apply across production, sales, and marketing—eliminate bottlenecks everywhere

Frequently Asked Questions

Q: Won’t automation eliminate jobs in my print shop?

A: No. Automation eliminates tedious tasks, not jobs. Your skilled operators shift from firefighting to strategic optimization. Companies that implement automation typically retain employees better because work becomes more meaningful and less exhausting. You’re not replacing people—you’re amplifying their impact.

Q: How quickly can we see ROI from print workflow automation?

A: Most shops see measurable improvements within 90 days—reduced makeready time, fewer customer service issues, and better on-time delivery. Full financial ROI typically manifests within 6-12 months through reduced rework, increased throughput, and improved capacity utilization without additional equipment investment.

Q: What’s the difference between automation and just buying new equipment with digital features?

A: Equipment automation (like inline color control) solves specific production problems. Workflow automation solves systemic process problems across intake, prepress, production, and delivery. The highest ROI comes from fixing workflow friction first—then your equipment investments deliver even better returns.

Q: How do I know which automation investments to prioritize?

A: Start with your biggest bottleneck. Ask: “Where do jobs slow down most?” and “Where does rework happen most frequently?” Fix those first. The diagnostic questions in this article will help you identify priority areas based on actual pain points, not vendor promises.

Q: Can smaller print shops benefit from automation, or is it only for large operations?

A: Smaller shops often see proportionally larger benefits because they’re more resource-constrained. Cloud-based automation tools have made sophisticated workflow management accessible at every scale. The key is selecting solutions that match your volume and complexity—you don’t need enterprise-level systems to eliminate common bottlenecks.

Your Competitive Edge Is Hidden in Your Workflow

In my experience guiding print operations through transformation, I’ve learned this: The shops that grow fastest are the ones that stop tolerating inefficiency.

They don’t wait for perfect conditions. They don’t blame external factors they can’t control. They systematically identify friction, eliminate it, and compound those improvements over time.

Your competitors are making this shift right now. The question isn’t whether automation will reshape commercial print—it’s whether you’ll lead that transformation or react to it.

The margin killers I’ve outlined aren’t hypothetical. They’re operating in your shop today, quietly eroding profitability while you focus on more visible problems. But unlike material costs or market conditions, these are problems you can actually fix.

Start with the diagnostic questions. Be honest about where friction lives in your operation. Identify the one bottleneck that causes the most pain. Then fix it systematically.

That’s how transformation actually happens—not through grand visions, but through relentless elimination of unnecessary friction.

Ready to Find Your Hidden Margin Killers?

I’ve created a comprehensive Print Shop Workflow Efficiency Audit that walks you through a systematic assessment of your operation. It’s the same diagnostic framework I use when evaluating print shops for automation opportunities.

If you’d like to get this audit or talk through your specific situation, schedule a 30-minute strategy call. I’ll help you identify your top three automation priorities and create a practical 90-day implementation roadmap.

Let’s fix what’s broken and unlock the margins hiding in your workflow.